Aerogel Thermablok

The revolutionary ThermaBlok® insulation technology, used in the Space Shuttle, has the highest insulation value of any material known. Thermablok is now available for use in building construction and energy efficiency retrofits. Most heat transmission through walls is directly through studs to the drywall, known as “thermal bridging”. Thermablok breaks this thermal bridging link.

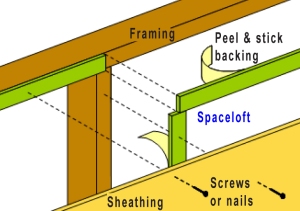

Thermablok manufactures aerogel in 1-1/2″ wide strips rather than broad sheets. In stud wall construction, the cavity between the studs is filled with insulation, but the studs themselves can conduct heat and cold, a process known as “thermal bridging,” which reduces the thermal performance of the wall. By covering the studs with strips of aerogel insulation before the interior drywall or exterior sheathing is applied, the thermal bridging is broken, and the thermal performance of the wall can increase by 30% or more. This can be an efficient use of aerogel material in a cost-effective way.

Thermablok strips can be installed on the exterior of the studs during new construction, or can be applied on the interior during remodeling as well as new construction. This makes it suitable for energy efficiency retrofits. As with Spaceloft blankets, because Thermablok is so thin (about 1/4″ once installed), it can be used to improve performance without taking away great amounts of space from inside the building.

Suggested retail price for Thermablok tape is $1.99/ft.

Advantages

Very significant saving in energy costs, Stimulus Package tax credits up to 30% available for residential retrofits

100% recyclable, Contains no ozone depleting substances, Uses >30% recycled content, Composite material consisting of over 95% air, Hydrophobic, unaffected by moisture, mold or water, Easily applied via stick-on-back, “Class A” fire rated, Economical, Virtually no weight means low cost (+ low emissions) shipping, Adds acoustical isolation, Is not affected by age as it does not react with moisture of the atmosphere, and Made in USA

Availability

Thermablok Thermal and Acoustic Isolation Systems

6900 Interbay Blvd. Tampa Fl 33616

Phone +1-813-980-1400 Fax +1-813-549-2653

http://thermablok.com/index.html

Filed under: Materials, Research, Skins, aerogel, insulation